Introduction

The COVID-19 pandemic has accelerated digital adoption in manufacturing, transforming customer interactions and pushing the industry towards cloud-based solutions for more efficient, customer-focused operations. This shift has emphasized the importance of Industry 4.0 technologies, like automation and AI, making manufacturers more responsive to challenges.

Insight:

Based on the Wikipedia, the term “Fourth Industrial Revolution,” also known as “4IR” or “Industry 4.0,” refers to the current era of technological advancement that began to gain prominence around 2016.

This concept, introduced by Klaus Schwab, the founder and executive chairman of the World Economic Forum, highlights a transformation in industrial capitalism driven by innovations.

This era is characterized by the convergence of technologies such as artificial intelligence, gene editing, and advanced robotics, which merge the physical, digital, and biological spheres, fundamentally changing how we live and work.

The crisis has revealed the limitations of existing digital infrastructures, underscoring the need for enhanced IT/OT systems. Companies lagging in digital adoption found it harder to cope, highlighting the digital divide.

Manufacturers are now prioritizing technologies that promote remote working, enhance supply chain connectivity, and increase operational transparency. This strategic shift aims for long-term resilience and adaptability.

Did you know, that based on the Salesforce Manufacturing MFG Report:

- 81% manufacturers consider it a crucial or high priority to transition their planning processes to the cloud

- 70% manufacturers report that their criteria for success have evolved

- 8 out of 10 manufacturers acknowledge the need for both innovative strategies and tools to achieve accurate forecasting.

Curious about statistics for other industries? You can find detailed implementation steps, valuable insights, cost information, and much more about Salesforce in small businesses within the Salesforce for Small Business Implementation Guide.

Remarkably, the pandemic has condensed the timeline for digital innovation, with companies deploying digital solutions at unprecedented speeds. This rapid transformation suggests a significant leap forward in digital product development and service enhancement.

Moving forward, the focus is on strategically implementing digital initiatives that align with key business goals. Embracing cloud-based and IoT solutions, companies aim for quick, scalable implementations to ensure sustainability and competitive advantage in a post-pandemic world.

This comprehensive shift towards digital resilience and customer-centric operations marks a new era in manufacturing, driven by the urgent need for agility and efficiency in response to global challenges.

In this article we aim to cover such topics as:

- Overview of Salesforce Manufacturing Cloud

- Salesforce Manufacturing Cloud Data Architecture and Data Model

- Types of Manufacturers That Can Benefit from Salesforce Manufacturing Cloud

- Original Equipment Manufacturers (OEMs)

- Production Suppliers

- Distribution or Aftermarket Manufacturers

- Process Manufacturers

- Oil and Gas Producers

- Companies Managing Run-rate, Ongoing, or Long-term Business

- Companies Focused on Service Lifecycle Orchestration

- Companies Seeking to Drive Greater Partner Engagement

- Cost Considerations of Salesforce Manufacturing Cloud

- Implementation Steps for Salesforce Manufacturing Cloud

- Possible Issues to Beware During Implementation of Salesforce Manufacturing Cloud

- Team Setup for Implementing Salesforce Manufacturing Cloud

- Key Salesforce Apps for Manufacturing

- Salesforce Integrations Specific to the Manufacturing Industry

- Frequently Asked Questions for Salesforce Manufacturing Cloud

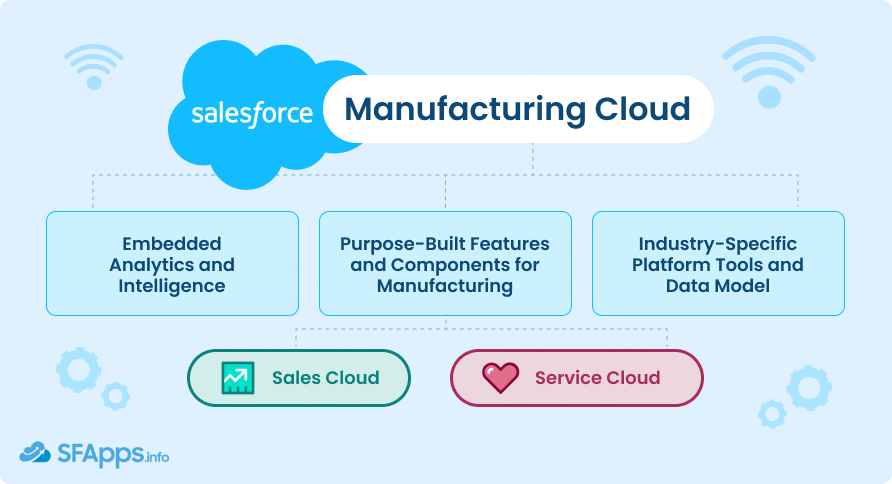

Overview of Salesforce Manufacturing Cloud

In the manufacturing sector, the ability to quickly adapt and respond to market changes is not just an advantage—it’s a necessity. Salesforce Manufacturing Cloud is at the forefront of this transformation, offering a robust solution tailored specifically for the manufacturing industry. This platform is designed to seamlessly connect sales and operations, paving the way for unmatched efficiency and strategic decision-making. Here’s an updated look at the comprehensive benefits and innovative features that define Salesforce Manufacturing Cloud:

Transformative Benefits:

- Improved Forecasting Accuracy: Integrating sales and operations data allows for precise demand forecasting. This not only minimizes the risk of inventory surplus or shortages but also optimizes service levels, ensuring that manufacturers can respond more dynamically to market demands.

- Enhanced Operational Visibility: With Salesforce Manufacturing Cloud, manufacturers gain comprehensive visibility into their processes. This real-time insight allows for informed decision-making throughout the production cycle, from planning to delivery, ensuring that every action is based on the latest data.

- Streamlined Sales Agreement Management: The platform simplifies the process of creating and managing sales agreements, enhancing efficiency and compliance. This results in improved customer satisfaction by ensuring that all sales commitments are accurately met and managed.

- Seamless Operations Integration: By directly linking sales forecasting with production planning, the platform ensures a synchronized response to market demands. This alignment eliminates inefficiencies and minimizes waste, creating a leaner manufacturing process.

Key Features of Salesforce Manufacturing Cloud

- 360-Degree View of Customers & Sales Forecasting: This feature unifies customer data across the business, from sales and service to e-commerce and supply chain, providing a holistic view that enables personalized customer engagement and more accurate sales forecasting.

- Omnichannel Commerce & Field Service Management: Salesforce Manufacturing Cloud facilitates a cohesive buying experience across multiple channels while managing field services effectively. This ensures that technicians are well-equipped to handle tasks efficiently, enhancing customer service and operational continuity.

- AI-Powered Insights & Supply Chain Visibility: Leveraging AI capabilities, the platform offers predictive insights and automated task management, improving sales, service, and marketing efforts. Moreover, it provides extensive visibility into the supply chain, allowing for better assessment of supplier performance and risk management.

- Connected Product Design & Asset Management: The platform supports the digital transformation of product development and asset management processes. It allows for collaborative work on product records and offers real-time insights into the health and performance of production assets, ensuring optimal utilization and preventive maintenance.

By integrating these benefits and features into their operations, manufacturers can significantly enhance their productivity, efficiency, and customer satisfaction, positioning themselves strongly in a competitive market. Salesforce Manufacturing Cloud stands out as a comprehensive solution that not only addresses the current needs of the manufacturing industry but also anticipates future challenges, ensuring businesses remain agile and resilient.

Salesforce Manufacturing Cloud Data Architecture and Data Model

At the heart of Salesforce Manufacturing Cloud’s effectiveness is its sophisticated data architecture and model, specifically designed to cater to the complexities of the manufacturing sector. This framework not only enhances data flow and accessibility but also ensures that the information remains secure, reliable, and ready for insightful analytics. Let’s break down the critical components of this architecture and understand its impact on manufacturing operations:

Core Aspects of Salesforce Manufacturing Cloud Data Model

- Unified Data Structure: At its essence, Salesforce Manufacturing Cloud brings together data from a myriad of sources — including sales data, operational metrics, and inputs from external partners — into a single unified system. This consolidated approach offers all involved parties access to a consistent and reliable data set, which is critical for informed decision-making and strategic planning. The integration ensures a holistic view of operations, empowering manufacturers with the ability to make decisions based on a “single source of truth.”

- Customization and Scalability: Recognizing the diverse nature of manufacturing operations, Salesforce Manufacturing Cloud’s data architecture is built for customization. It allows businesses to tailor the platform to their specific requirements, ensuring that the system aligns with their operational processes and is capable of scaling in tandem with business growth. This flexibility is pivotal for manufacturers aiming to adapt the system as their operations evolve over time.

Salesforce Manufacturing Cloud Integration and Extension Capabilities

- Seamless Integration with Enterprise Systems: A standout feature of Manufacturing Cloud is its seamless integration capabilities with other enterprise systems such as ERP (Enterprise Resource Planning), CRM (Customer Relationship Management), and PLM (Product Lifecycle Management). Salesforce’s robust API (Application Programming Interface) framework facilitates this integration, enabling real-time data exchange and enhancing the interoperability between different systems. This interconnectedness ensures that data flows smoothly across the enterprise, bridging gaps between disparate systems and departments.

- Expansive Ecosystem for Third-party Applications: The platform’s open architecture is designed to support a wide array of third-party applications and services. This enables businesses to extend the platform’s functionality, incorporating additional tools and services available within the Salesforce ecosystem to meet their specific needs. The ability to integrate with third-party apps significantly enhances the platform’s versatility, allowing manufacturers to leverage external innovations and solutions seamlessly.

Salesforce Manufacturing Cloud Data Utilization and Security

- Insight Generation through Einstein Analytics: Embedded within Salesforce Manufacturing Cloud is Einstein Analytics, a powerful tool that transforms raw data into actionable insights. Manufacturers can leverage these insights to streamline their operations, enhance demand forecasting accuracy, and improve customer service. The analytics component is crucial for identifying operational efficiencies and optimizing processes based on data-driven insights.

- Real-time Data Processing: The architecture’s support for real-time data processing ensures that manufacturers have access to up-to-the-minute information. This immediacy is vital for making timely decisions in the fast-paced manufacturing environment, allowing businesses to react swiftly to changing market conditions and operational challenges.

Ensuring Data Security and Compliance

- Robust Security Protocols: Manufacturing Cloud employs stringent security measures, including data encryption and access controls, to safeguard sensitive data. These protocols are essential for maintaining data integrity and protecting against unauthorized access, ensuring that manufacturers can trust the security of their data within the platform.

- Adherence to Industry Standards: The platform is designed with compliance in mind, adhering to various industry standards and regulations. This compliance aspect is particularly important for manufacturers concerned about data governance and regulatory requirements, providing assurance that the system meets established standards for data handling and privacy.

Salesforce Manufacturing Cloud’s data architecture and model are instrumental in transforming manufacturing operations. By offering a unified, flexible, and secure data environment, it empowers manufacturers to harness the full potential of their data, driving efficiencies, fostering innovation, and supporting growth. The platform’s integration capabilities, combined with its focus on security and compliance, make it an invaluable tool for modernizing manufacturing operations and achieving digital transformation goals.

Types of Manufacturers That Can Benefit from Salesforce Manufacturing Cloud

Salesforce Manufacturing Cloud offers a customizable platform tailored to suit the unique needs of various segments within the manufacturing industry. This versatility ensures that companies can leverage the cloud to streamline operations, enhance customer relationships, and boost efficiency, regardless of their specific manufacturing processes or products. Here’s a breakdown of the types of manufacturers that stand to benefit significantly from implementing Salesforce Manufacturing Cloud, along with the unique advantages it offers to each.

Original Equipment Manufacturers (OEMs)

- Characteristics: OEMs specialize in producing components or final products that may be marketed by another manufacturer.

- Benefits: Salesforce Manufacturing Cloud aids in managing complex supply chains, improving collaboration with dealers and suppliers, and providing deeper insights into customer and product performance.

Production Suppliers

- Characteristics: Suppliers focus on producing parts or materials used in the manufacture of other products.

- Benefits: The platform enhances supplier relationship management, streamlines procurement processes, and offers precise tracking of material quality and delivery schedules.

Distribution or Aftermarket Manufacturers

- Characteristics: These manufacturers produce accessories, replacements, or enhancements for existing products.

- Benefits: They can gain from improved inventory management, enhanced distribution logistics, and more effective market demand forecasting with Salesforce Manufacturing Cloud.

Process Manufacturers

- Characteristics: Involves production of goods such as chemicals, food and beverages, or pharmaceuticals, where the product is produced in bulk and cannot be disassembled into its constituent parts.

- Benefits: The cloud supports formula and recipe management, compliance with health and safety regulations, and optimization of production schedules to minimize waste.

Oil and Gas Producers

- Characteristics: Companies in this sector explore, extract, and process oil and gas products.

- Benefits: Salesforce Manufacturing Cloud can optimize supply chain logistics, improve safety and compliance tracking, and enhance forecasting of production needs.

Companies Managing Run-rate, Ongoing, or Long-term Business

- Characteristics: These businesses have steady, continuous production or service offerings, often under long-term contracts.

- Benefits: The platform enables better contract management, demand planning, and customer relationship management over the lifecycle of long-term agreements.

Companies Focused on Service Lifecycle Orchestration

- Characteristics: These companies prioritize managing the end-to-end service experience for their products or services.

- Benefits: Salesforce Manufacturing Cloud facilitates the automation of service processes, improving customer support, complaint resolution, and product issue management across departments.

Companies Seeking to Drive Greater Partner Engagement

- Characteristics: Focuses on enhancing collaboration and communication with business partners, including suppliers, distributors, and resellers.

- Benefits: The platform offers tools for better partner relationship management, collaborative planning, and shared access to critical data and analytics.

By targeting these specific segments, Salesforce Manufacturing Cloud empowers manufacturing companies to address their unique challenges and operational requirements. The cloud’s comprehensive tools and features are designed to boost operational agility, improve efficiency, and elevate the customer experience, making it an invaluable asset for manufacturers looking to innovate and thrive in a competitive marketplace.

Implementing Salesforce Manufacturing Cloud can transform commercial operations, enhance service experiences, and streamline partner engagement, providing a solid foundation for manufacturers aiming to excel in their respective fields.

Cost Considerations of Salesforce Manufacturing Cloud

Choosing Salesforce Manufacturing Cloud is a decisive step towards modernizing your manufacturing operations and improving customer engagement. With its specialized offerings, it’s essential to grasp the pricing structure to prepare an accurate budget and financial strategy. Here is an updated breakdown of the pricing for the various Salesforce Manufacturing Cloud packages, along with additional financial considerations for a comprehensive overview.

Salesforce Manufacturing Cloud Pricing Breakdown

- Manufacturing Cloud — Sales: Priced at $250 USD per user per month (billed annually), this package equips teams with the tools to manage sales operations, including tracking opportunities, agreements, forecasts, and projects.

- Manufacturing Cloud — Service: Also at $250 USD per user per month (billed annually), this version focuses on enhancing service delivery and creating new revenue opportunities, vital for service-oriented manufacturing sectors.

- Manufacturing Cloud — Sales and Service: Offering a holistic approach at $275 USD per user per month (billed annually), this comprehensive package merges sales and service functionalities, providing a unified platform for customer-centric operations.

- Manufacturing Cloud — Einstein 1 for Sales: For manufacturers seeking advanced AI capabilities, this option is available at $650 USD per user per month (billed annually), delivering an optimized sales experience tailored to manufacturing industry needs.

Broader Financial Implications

While subscription fees form the core of the investment, ancillary costs such as system customization, integration with existing infrastructure, Salesforce manufacturing consulting for implementation, and training should also be accounted for. A meticulous examination of these areas against anticipated efficiency improvements and ROI can facilitate informed financial planning.

Justifying the Expense

- Operational Efficiency and Revenue Enhancement: The promise of operational streamlining and new revenue pathways can substantially counterbalance the initial and ongoing expenses. Conducting a comprehensive ROI analysis that considers both tangible and intangible benefits will illuminate the financial wisdom of this investment.

- Strategic Advantages: Beyond quantifiable financial outcomes, the strategic benefits of improved decision-making, heightened customer satisfaction, and market adaptability warrant consideration in the investment decision.

Navigating the Financial Landscape

- Phased Deployment: Adopting a staged implementation strategy can help manage financial commitments by prioritizing modules that address immediate business needs.

- Financial Negotiation and Customization: Engaging in discussions with Salesforce and its partners can uncover opportunities for customized pricing or payment plans that align with your business size and fiscal constraints.

By presenting a detailed view of the pricing alongside a strategic analysis of the costs and benefits, businesses can better navigate the financial considerations of implementing Salesforce and Manufacturing Cloud. This approach ensures that the investment not only aligns with operational objectives but also supports broader business goals, paving the way for a successful digital transformation in manufacturing.

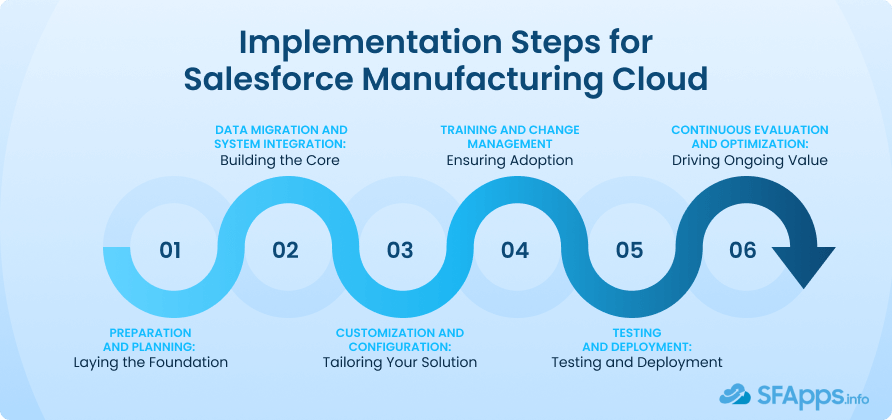

Implementation Steps for Salesforce Manufacturing Cloud

Embarking on the Salesforce Manufacturing Cloud journey is a strategic move that can transform your manufacturing operations. This careful process, when executed well, brings your production, sales, and operations teams closer, enhancing efficiency and responsiveness. By leveraging the capabilities of Salesforce Manufacturing Cloud, you’re not just implementing a new system. You’re investing in a solution that optimizes inventory, improves forecasting, and encourages collaboration across departments. Although the journey might seem complex, it sets your business up for a competitive edge, allowing you to quickly adapt to market changes with accuracy and efficiency. Here’s a deeper look into each step, designed to provide actionable guidance and ensure a smooth transition.

1. Preparation and Planning: Laying the Foundation

- Comprehensive process review: Conduct a detailed audit of your current manufacturing, sales, and service processes. This review should identify inefficiencies, data silos, and areas where automation can bring immediate benefits.

- Strategic objective setting: Beyond identifying goals, classify them into short-term wins and long-term strategic objectives. This dual-focus approach helps maintain momentum and demonstrates value early in the implementation.

- Cross-functional team assembly: Ensure the implementation team includes champions from each department who understand their domain’s intricacies and can advocate for solutions that address specific challenges.

2. Data Migration and System Integration: Building the Core

- Detailed data strategy: Develop a data migration strategy that includes mapping out data sources, establishing data cleaning procedures, and defining data governance policies to maintain data integrity post-migration.

- Integration blueprint: Design an integration plan that outlines how Salesforce Manufacturing Cloud will communicate with existing systems. This blueprint should specify the data flow, integration points, and any custom integration solutions needed.

3. Customization and Configuration: Tailoring Your Solution

- Use case identification: Identify key use cases that Salesforce Manufacturing Cloud will address. Tailoring the platform to these use cases ensures it solves real-world problems and adds value to your operations.

- Feature customization: Leverage Salesforce’s Lightning App Builder and Flow for customization. Prioritize customizations that align with your identified use cases and offer the most significant operational impact.

4. Training and Change Management: Ensuring Adoption

- Role-specific training programs: Develop training programs tailored to the various roles within your organization. This approach ensures that each team member understands how to use the platform effectively in their day-to-day tasks.

- Proactive change management: Establish a change management committee tasked with monitoring the adoption process, addressing resistance, and championing the benefits of Salesforce Manufacturing Cloud across the organization.

5. Testing and Deployment: Launching with Confidence

- Structured pilot program: Select a diverse group of pilot users who can provide feedback from various operational perspectives. Structuring your pilot program around specific scenarios or processes can help uncover any issues before a full-scale rollout.

- Deployment phases: Consider deploying in phases, starting with departments or processes where the impact can be quickly realized. This phased approach allows for learning and adjustments as you expand the implementation.

6. Continuous Evaluation and Optimization: Driving Ongoing Value

- Performance metrics and KPIs: Establish clear metrics and KPIs to measure the system’s performance. Regularly review these metrics to assess whether the platform is meeting your business objectives.

- Iterative improvement process: Create an ongoing process for collecting user feedback, analyzing system performance, and implementing improvements. This iterative approach ensures that Salesforce Manufacturing Cloud continues to evolve with your business needs.

By adding these detailed insights into each step of the implementation process, businesses can better prepare for and navigate the complexities of deploying Salesforce Manufacturing Cloud. This comprehensive approach not only facilitates a smoother implementation but also maximizes the long-term benefits of the platform, driving significant improvements in manufacturing operations.

Possible Issues to Beware During Implementation of Salesforce Manufacturing Cloud

Implementing an advanced system like Salesforce Manufacturing Cloud is a significant step towards revolutionizing manufacturing operations. However, this journey comes with its set of challenges that, if not properly managed, can impede the smooth transition to and optimization of the new system. Understanding these potential pitfalls and preparing strategies to mitigate them can significantly streamline the implementation process. Let’s delve into some common challenges and their effective solutions:

1. Ensuring Data Integrity

- Challenge: The presence of inconsistent, duplicate, or incomplete data can disrupt the migration to Salesforce Manufacturing Cloud, affecting system efficiency.

- Solution: Initiate the process with a comprehensive data audit and cleanse to rectify any inaccuracies. Employ robust data validation tools and set up continuous data governance practices to maintain high data quality.

2. Streamlining System Integration

- Challenge: Merging Salesforce Manufacturing Cloud with existing platforms like ERP, CRM, and SCM systems can introduce complexities, risking data isolation and integration mishaps.

- Solution: Craft a precise integration blueprint detailing all data interactions, and utilize specialized middleware or APIs for a smooth integration process. Engaging experts for complex integration tasks may also be beneficial.

3. Managing Customization

- Challenge: Over-customizing the system can lead to operational heaviness, making updates difficult and possibly misaligning with actual business workflows.

- Solution: Prioritize customizations that offer substantial business value. Where feasible, rely on Salesforce’s built-in functionalities and explore its app marketplace for additional needs without overcomplicating the system.

4. Enhancing User Adoption

- Challenge: Users might resist shifting from familiar legacy systems to a new platform, potentially compromising the effectiveness of the Salesforce Manufacturing Cloud.

- Solution: Deploy targeted change management and training initiatives, addressing the specific needs of different user groups. Early engagement with users for input can also help build ownership and ease the transition.

5. Providing Adequate Support

- Challenge: Underestimating the need for continuous support post-implementation can result in user dissatisfaction and underperformance of the system.

- Solution: Set up a proficient support team ready to tackle both user inquiries and technical issues. Engaging a Salesforce Managed Services provider can offer additional support and continual system enhancements.

6. Ensuring Mobile and Remote Access

- Challenge: In the modern, flexible work environment, overlooking the importance of access from anywhere can reduce the effectiveness of the system.

- Solution: Utilize the mobile capabilities of Salesforce Manufacturing Cloud to guarantee that users can securely use the system, no matter where they are. This ensures that the platform remains fully functional and accessible for all users, enhancing productivity and responsiveness across your organization.

7. Maintaining Compliance and Security

- Challenge: Adhering to industry regulations and maintaining stringent security measures can be complex but is crucial.

- Solution: Collaborate with Salesforce experts to tailor the system to meet specific regulatory standards. Continuously review and update security measures and conduct regular audits to uphold strict compliance and security norms.

By proactively addressing these challenges with the outlined strategies, companies can navigate the complexities of implementing Salesforce Manufacturing Cloud more smoothly. This forward-thinking approach not only facilitates a more efficient implementation but also maximizes the platform’s benefits, aligning closely with organizational objectives and driving operational excellence in manufacturing.

Team Setup for Implementing Salesforce Manufacturing Cloud

A successful deployment of Salesforce Manufacturing Cloud relies heavily on the formation of a proficient and cohesive team. The expertise and collaborative effort of this team are crucial in overcoming the challenges associated with implementation, customization, and integration. Here’s a breakdown of the essential roles for a successful implementation team and what they bring to the table:

1. Project Manager (PM)

- Key Responsibilities: Leads the entire project, ensuring it remains on track, on budget, and resolves any issues between business and technical teams.

- Skills Required: Leadership, effective communication, project management expertise, and prior experience with Salesforce projects.

2. Salesforce Architect

- Key Responsibilities: Designs the system architecture to ensure it meets technical requirements and integrates seamlessly with current systems. Make sure to check Salesforce architect interview questions, if you are looking to hire a Salesforce Architect for your team.

- Skills Required: In-depth understanding of the Salesforce ecosystem, system integration experience, and familiarity with manufacturing industry needs.

3. Business Analysts (BAs)

- Key Responsibilities: Identifies business needs, aligns processes with Salesforce Manufacturing Cloud capabilities, and spots improvement opportunities. To hire right Salesforce BA for your team, make sure to check Salesforce Business Analyst interview questions.

- Skills Required: Analytical prowess, manufacturing operations insight, and knowledge of Salesforce features.

4. Salesforce Developers

- Key Responsibilities: Salesforce developers tailor the Salesforce platform to meet specific business requirements, develops custom features, and handles system integrations.

- Skills Required: Proficiency in Apex (Salesforce apex interview questions), Visualforce, Lightning platform (Salesforce lightning interview questions), and an understanding of manufacturing workflows.

5. Data Specialists

- Key Responsibilities: Oversees data migration, maintains data quality, sets up data governance, and integrates various data sources into the Salesforce platform.

- Skills Required: Data migration and integration skills, proficiency with data management tools, and knowledge of Salesforce data architecture.

6. Change Management and Training Specialists

- Key Responsibilities: Crafts and implements a change management strategy to boost user adoption, develops training materials, and provides ongoing support.

- Skills Required: Excellent communication, experience in change management, and understanding of Salesforce training techniques.

7. Quality Assurance (QA) Analysts

- Key Responsibilities: Ensures the system is bug-free, performs as expected, and fulfills all business requirements through thorough testing.

- Skills Required: QA expertise, familiarity with Salesforce testing environments, and meticulous attention to detail.

8. Support Team

- Key Responsibilities: Delivers continuous support after going live, helps users navigate the system, and resolves emerging issues.

- Skills Required: Problem-solving skills, in-depth knowledge of Salesforce Manufacturing Cloud, and a commitment to outstanding customer service.

9. Salesforce Administrator

- Key Responsibilities: The Salesforce Administrator, Salesforce manufacturing CRM consultant, configures the system, manages user accounts, and ensures the platform aligns with business processes. They act as the primary point of contact for internal users to troubleshoot issues, manage system updates, and implement security measures. Additionally, they customize the platform to meet user needs, create reports and dashboards, and maintain overall system health. To hire the right Salesforce Administrator, make sure to check Salesforce administrator interview questions and answers in our blog.

- Skills Required: Comprehensive knowledge of Salesforce functionalities, strong problem-solving abilities, proficiency in creating reports and dashboards, and excellent communication skills to gather user requirements and provide training. Experience with system maintenance, user management, and understanding of security best practices are also essential.

By bringing together a team that covers these roles, you’re setting up your Salesforce Manufacturing Cloud implementation for success. Each member plays a pivotal role in navigating the complexities of the project, ensuring a smooth transition and maximizing the value of the platform for your manufacturing operation.

Key Salesforce Apps for Manufacturing

Salesforce Manufacturing Cloud provides a solid foundation for streamlining manufacturing operations, but its capabilities are greatly enhanced by a range of apps available on the Salesforce AppExchange. These apps address specific manufacturing needs, from inventory management to customer service, amplifying the ecosystem’s utility. Here’s a closer look at some notable Salesforce apps beneficial for manufacturing, alongside additional recommended apps for various operational needs:

Apps for Enhanced Quotes and Proposals

DocuSign CLM

DocuSign CLM (Contract Lifecycle Management) for Salesforce empowers organizations to boost their renewal rates, enhance overall productivity, and accelerate growth. This tool simplifies and streamlines the entire agreement process—from preparing and customizing contracts to facilitating collaboration and managing approvals efficiently. It provides a secure and centralized repository for storing all agreements, making them readily accessible and easy to find. By integrating DocuSign CLM with Salesforce, companies can ensure that their contract management processes are more organized, transparent, and efficient, leading to faster deal closures and improved operational effectiveness. This seamless integration also aids in ensuring compliance and reducing risks associated with contract management, ultimately contributing to a smoother, more reliable workflow.

Tacton CPQ for Salesforce®

The integration of Tacton CPQ with Salesforce CRM transforms the sales experience by introducing advanced capabilities in product configuration, pricing, and quoting, designed specifically for the manufacturing sector. This powerful combination elevates Salesforce CRM beyond its standard functionalities, enabling sales teams to deliver precise and rapid proposals to customers. More about CPQ can be found in the CPQ Questions article.

Apps to Amplify Sales through Partnerships

Tavant Warranty On-Demand

Tavant Warranty On-Demand (TWOD) stands out as the sole native warranty management application within the Salesforce ecosystem, designed specifically to facilitate a comprehensive, closed-loop warranty management process. This innovative app assists clients in achieving significant reductions in warranty-related expenses, enhancing the recovery of costs from suppliers, and boosting the efficiency of aftermarket services.

Apps for Comprehensive Product Management

Propel | PLM, QMS & PIM

Propel stands out as the sole platform on the Salesforce ecosystem that seamlessly integrates Product Lifecycle Management (PLM), Quality Management System (QMS), Product Information Management (PIM), and supplier management. This comprehensive blend offers businesses a unified and continuous flow of product information, facilitating effortless collaboration throughout the entire value chain. By housing PLM, QMS, PIM, and supplier management in one solution, Propel enables organizations to streamline processes, enhance product quality, and speed up time-to-market. It bridges gaps between different departments and stakeholders, from design and production to quality control and distribution, ensuring that everyone has access to the latest product details and standards. This holistic approach not only simplifies internal and external communication but also drives efficiency and innovation by aligning all facets of product development and management on the powerful Salesforce platform.

Enterprise Quality Management Suite by ComplianceQuest (EQMS)

ComplianceQuest stands out as an innovative, AI-driven Quality Management System (QMS) designed exclusively for Salesforce. This cutting-edge solution is tailored specifically for the life sciences and manufacturing sectors, aiming to accelerate both product and process innovation. By leveraging artificial intelligence, ComplianceQuest enables companies to significantly reduce risks associated with their operations while promoting a culture of continuous improvement. Built from the ground up on the Salesforce platform, it integrates seamlessly into existing workflows, enhancing data visibility and facilitating more informed decision-making. Whether you’re looking to streamline compliance processes, enhance product quality, or drive operational excellence, ComplianceQuest provides a flexible and comprehensive toolset to meet the unique quality management needs of today’s dynamic industries.

Apps Linking Manufacturing to Sales

Rootstock Cloud ERP for Manufacturing

Rootstock Software stands out as a global provider of cloud-based Salesforce manufacturing ERP solutions, specifically designed to operate seamlessly on the Salesforce Platform. By integrating Rootstock ERP with Salesforce CRM, manufacturing, distribution, and supply chain organizations are equipped with a unified platform that not only supports but also enhances their ability to expand and efficiently manage their operations. This Salesforce manufacturing integration leverages the strengths of both Salesforce’s advanced CRM capabilities and Rootstock’s comprehensive ERP functionalities. Together, they offer a holistic view of the customer journey, from initial contact through production, inventory management, and beyond. This synergy enables businesses to streamline processes, improve customer relationships, and achieve a higher level of operational excellence, all within the familiar and collaborative environment of Salesforce.

Revenova TMS for 3PLs, Freight Brokers, Carriers, and Shippers

RevenovaTMS addresses the complex operational and IT challenges that Logistics Service Providers (3PLs), Freight Brokers, Carriers, and Shippers encounter by offering a comprehensive multimodal Transportation Management System (TMS). This innovative solution is built on the world’s leading CRM platform, Salesforce.com, ensuring a seamless integration of transportation management capabilities with robust customer relationship management features.

By leveraging the power of Salesforce, RevenovaTMS enables users to manage freight operations across various modes of transportation, including road, rail, air, and sea, all from a single, user-friendly interface. This integration not only streamlines the logistics workflow but also enhances visibility, efficiency, and collaboration within the supply chain. Users can benefit from real-time data and analytics, customizable dashboards, and the ability to automate critical processes, leading to improved decision-making and operational excellence. With RevenovaTMS, logistics organizations can effectively navigate the complexities of the modern transportation landscape, while also capitalizing on the customer engagement and management tools offered by Salesforce.

Apps for Project Management

TaskRay Work Management and Customer Onboarding

TaskRay transforms how project teams operate by seamlessly integrating comprehensive project and resource management capabilities directly within Salesforce. This 100% native app not only automates routine tasks, freeing up valuable time for your project teams, but it also fosters unparalleled collaboration with customers and amongst team members. By embedding powerful work management tools into the Salesforce ecosystem, TaskRay establishes a unified platform for managing projects. This integration ensures that all stakeholders have access to a single source of truth, enhancing transparency, efficiency, and overall project success. With TaskRay, teams can easily track project progress, allocate resources more effectively, and maintain open lines of communication, all within the familiar environment of Salesforce.

Leankor | Collaborative Work and Project Management Solution

Leankor, fully integrated within the Salesforce platform, transcends traditional project management by offering a comprehensive solution for managing complex projects. This app centralizes all project-related activities, enhancing team collaboration and ensuring all members stay aligned on project goals. It offers unparalleled visibility into project progress, enabling stakeholders to monitor key metrics and milestones closely. By streamlining communication and project tracking, Leankor empowers users to make informed decisions, aligning project outcomes with broader business strategies. This deep integration with Salesforce ensures that users benefit from a seamless experience, leveraging the platform’s robust capabilities to drive projects towards successful completion while fostering an environment of efficiency and strategic advancement.

Apps for Human Resources

Sage People

Sage People is a comprehensive and flexible cloud-based HR and People management system, designed to cater to global workforce needs. Built on the robust Salesforce platform, it offers a wide range of features that can be tailored to fit the unique requirements of businesses of any size. This end-to-end solution streamlines various HR processes, from recruitment and onboarding to performance management and workforce planning, enabling organizations to manage their human resources more efficiently and effectively. With its extensible architecture, Sage People allows for seamless integration with other systems and can be configured to support the evolving needs of your workforce, ensuring a scalable solution that grows with your business.

Xactly Incent®

Xactly enhances the effectiveness of your compensation strategies through the optimization of compensation plans, delivering increased efficiencies, improved timeliness, and heightened accuracy. By integrating Xactly with Salesforce, you unlock the potential to significantly boost sales performance and drive superior business outcomes. This powerful combination allows for a more streamlined approach to managing sales incentives, ensuring that compensation plans are not only aligned with your business goals but are also executed with precision. With Xactly’s advanced analytics and forecasting capabilities, businesses can make informed decisions that motivate their sales teams, leading to increased productivity and ultimately, stronger financial results. Leverage the synergy between Xactly and Salesforce to transform your sales compensation management into a strategic advantage that propels your company forward. More about Xactly can be found in the Xactly Incent Salesforce article.

Choosing the right apps from the Salesforce AppExchange can dramatically extend the functionality of Salesforce Manufacturing Cloud, equipping manufacturers with the tools needed to optimize operations further. When selecting apps, it’s essential to consider your specific operational challenges and requirements to ensure the best fit and maximize return on investment.

Salesforce Integrations Specific to the Manufacturing Industry

Salesforce Manufacturing Cloud extends its value far beyond its core functionality by seamlessly connecting with other essential systems used in the manufacturing sector. These integrations foster a cohesive ecosystem, ensuring data consistency and providing real-time insights throughout the manufacturing lifecycle. Below, we delve into five critical integrations that offer substantial benefits to manufacturers:

Salesforce Manufacturing Cloud and ERP Integration

Linking Salesforce Manufacturing Cloud with Enterprise Resource Planning (ERP) systems creates a unified view of sales and operational data. This vital integration synchronizes inventory levels, production schedules, and financial insights. This connection offers deeper operational visibility, elevates forecasting precision, and supports strategic decisions with a holistic view of business data.

Salesforce Manufacturing Cloud and PLM Integration

By integrating Product Lifecycle Management (PLM) tools with Salesforce, manufacturers streamline the journey from product design to production. This ensures comprehensive product data is easily accessible within Salesforce, enhancing collaboration across sales, engineering, and production teams. Results include faster product development cycles, shorter time-to-market, and heightened product quality, thanks to improved coordination and data sharing.

Salesforce Manufacturing Cloud and SCM Integration

Integrating Supply Chain Management (SCM) systems with Salesforce Manufacturing Cloud provides a transparent view into the supply chain. This covers everything from raw material sourcing to final product delivery. Manufacturers gain supply chain flexibility, reduce costs through better inventory management, and improve their ability to anticipate and address supply chain challenges.

Salesforce Manufacturing Cloud and IoT Integration

Connecting Internet of Things (IoT) devices and sensors with Salesforce Manufacturing Cloud empowers manufacturers with immediate data from production equipment and products in use. This integration enhances operational efficiency with predictive maintenance insights, improves product tracking, and enables the creation of new services based on usage data, opening avenues for innovation and customer engagement.

Salesforce Integration with Custom Applications

Custom applications designed to fit specific manufacturing processes can be integrated with Salesforce Manufacturing Cloud, ensuring these unique workflows remain aligned with wider sales and service strategies. Tailored integrations preserve proprietary operational processes while leveraging Salesforce’s analytical power, offering a balanced approach that combines customization with comprehensive data analysis.

For manufacturers considering Salesforce integrations, it’s crucial to evaluate how each connection aligns with your operational objectives. Prioritizing integrations that deliver meaningful improvements to efficiency, insight, and product lifecycle management can transform your manufacturing operations. Engaging with seasoned Salesforce integration specialists or consulting services ensures not only that the most impactful integrations are identified but also that their implementation is seamless and aligned with industry best practices. This strategic approach to integration unlocks the full potential of Salesforce Manufacturing Cloud, driving innovation, efficiency, and growth in the competitive manufacturing landscape.

Frequently Asked Questions for Salesforce Manufacturing Cloud

How does the Salesforce Manufacturing Cloud enhance forecasting in the manufacturing industry?

The Salesforce Manufacturing Cloud leverages integrated sales and operations data to significantly enhance forecasting accuracy, enabling manufacturers to adjust production plans based on real-time demand insights, a pivotal advantage for the manufacturing industry.

Can the Manufacturing Cloud Salesforce be tailored to specific manufacturing processes?

Absolutely, the Salesforce Manufacturing Cloud features a highly adaptable framework that can be customized to meet the unique requirements of various manufacturing processes, ensuring a perfect fit for specific operational workflows within the manufacturing Salesforce ecosystem.

What are the advantages of integrating ERP systems with the Salesforce Manufacturing Cloud?

Integrating ERP systems with the Salesforce Manufacturing Cloud streamlines the flow of operational and sales data, enhancing visibility across the board, which is critical for inventory management, collaborative forecasting, and overall operational efficiency in manufacturing Salesforce environments.

How does Salesforce for manufacturing industry improve customer relationship management?

Salesforce Manufacturing Cloud offers a comprehensive view of customer interactions, enabling more efficient management of sales agreements and quicker responses to customer needs, which is crucial for boosting customer satisfaction and loyalty in the manufacturing sector.

What analytics and reporting capabilities does the Salesforce Manufacturing Cloud offer?

The Salesforce Manufacturing Cloud provides advanced analytics and reporting tools, including customizable dashboards and AI-driven insights, enabling manufacturers to make data-driven decisions and stay ahead in the competitive manufacturing industry.

How does the Salesforce Manufacturing Cloud facilitate collaboration between sales and operations?

By offering a unified platform with integrated sales and operations data, the Salesforce Manufacturing Cloud fosters seamless collaboration, allowing teams to share insights, align on forecasts, and streamline production planning, demonstrating Salesforce’s impact on manufacturing.

Can the Manufacturing Cloud Salesforce integrate with other Salesforce products?

Yes, the Manufacturing Cloud in Salesforce seamlessly integrates with other Salesforce implementation solutions in manufacturing like Sales Cloud, Service Cloud, and Salesforce CPQ for manufacturing, creating a comprehensive suite for managing all facets of a manufacturing business.

What security measures does the Salesforce Manufacturing Cloud implement?

Adhering to Salesforce’s stringent security protocols, the Manufacturing Cloud offers robust features like user authentication, data encryption, and access controls, ensuring top-tier data security and compliance for manufacturing firms utilizing Salesforce.

How scalable is the Salesforce Manufacturing Cloud for the manufacturing industry?

Designed with growth in mind, the Salesforce Manufacturing Cloud scales with your business, accommodating increases in data, users, and operational complexity effortlessly, making it an ideal Salesforce manufacturing platform.

Does the Salesforce Manufacturing Cloud support access from mobile devices?

Certainly, the Salesforce Manufacturing Cloud supports mobile access, empowering sales and operations teams to access vital data and functionalities anytime, anywhere, thus enhancing operational flexibility and responsiveness for manufacturing entities on Salesforce.

How can a Salesforce Manufacturing Advisor benefit our manufacturing operations?

Designating a Salesforce Architect, or Consultant as your Salesforce Manufacturing Advisor can significantly transform your manufacturing operations through strategic implementation and optimization of Salesforce Manufacturing Cloud. These professionals bring specialized expertise in Salesforce solutions, tailored to meet the unique challenges and needs of the manufacturing sector.

What training resources are available for mastering the Salesforce Manufacturing Cloud?

Salesforce provides extensive training resources for the Manufacturing Cloud, including Trailhead for online learning, instructor-led courses, and specific manufacturing cloud certification Salesforce programs, designed to equip users with the expertise to leverage the full potential of Salesforce in manufacturing industry.

What is the typical timeframe for implementing the Salesforce Manufacturing Cloud in the manufacturing sector?

The timeframe for Salesforce Manufacturing Cloud implementation varies, depending on the complexity of business processes, customization needs, and integration requirements. Projects can range from a few weeks to several months, as detailed in the Salesforce Manufacturing Cloud implementation guide.

Final Thoughts

Salesforce Manufacturing Cloud goes beyond traditional CRM functionalities to meet the specific demands of the manufacturing industry. This platform transforms forecasting, unifies customer interaction data, and streamlines operations. By enabling seamless integration with essential technologies like ERP systems and IoT devices, it offers a holistic view of manufacturing processes, enhancing decision-making and interdepartmental collaboration.

The adaptability of Salesforce Manufacturing Cloud is further extended through compatible Salesforce apps and external integrations, allowing for a tailored approach to meet unique manufacturing needs. Whether improving product lifecycle management with Propel PLM or ensuring quality compliance via ComplianceQuest, Salesforce Manufacturing Cloud acts as a robust foundation for building a comprehensive solution ecosystem.

The journey towards digital transformation in manufacturing emphasizes the importance of a knowledgeable and certified team. A combination of roles, from project managers to Salesforce architects and data Salesforce manufacturing specialist, is vital for a smooth implementation process. Salesforce Manufacturing Cloud certification is equally crucial, arming team members with the expertise to unlock the platform’s full potential.

Implementing Salesforce Manufacturing Cloud varies in complexity based on business specifics but invariably leads to substantial benefits. Manufacturers can look forward to better operational visibility, increased efficiency, and deeper customer connections. Success hinges on strategic implementation planning and adaptability to evolving business needs.

In wrapping up, Salesforce Manufacturing Cloud signifies a forward leap for manufacturers poised to harness digital advancements. It paves the way for a more connected, efficient, and customer-focused operation. The transition to Salesforce Manufacturing Cloud is not just an upgrade—it’s a strategic move towards future-proofing manufacturing operations, where the possibilities for innovation and growth are boundless.

Dorian is a 4X Certified Salesforce Developer and Administrator with a start in the IT world as a CRM Admin in 2020. Since diving into Salesforce in 2021 via Trailhead and Focus on Force, he has achieved a Ranger Rank, earned several Superbadges, and bagged certifications including the Salesforce Certified Administrator, Platform App Builder, Associate and Platform Developer I by 2023. Dorian is very keen on continuous learning, always looks for fresh ways to improve his knowledge. He enjoys running, boxing, kickboxing and reading diverse kinds of books in his free time.

Previous Post

Previous Post Next Post

Next Post

Could you provide some examples of how manufacturers have used this feature to improve their operational efficiency? Specifically, I’m curious about any success stories involving supply chain management or production optimization. Thank you in advance!